| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Espure |

| Model Number : | GPd |

| Certification : | ISO |

| Price : | Negotiation |

| Payment Terms : | T/T |

| Supply Ability : | 30000 metric tons per year |

| Delivery Time : | 5-28 working days |

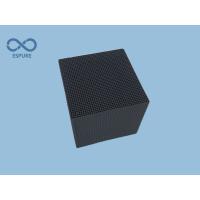

1200 mg/g Coal-Based Powdered Activated Carbon for Flue Gas Treatment

Product Introduction

The 1200mg/g Coal-Based Powdered Activated Carbon is produced from premium coal and meticulously processed to provide an outstanding solution for flue gas treatment. Through a thorough activation method, this high-quality powdered activated carbon is transformed into a fine, porous material with a significant surface area, greatly enhancing its capability to absorb contaminants.

| Specification | Value |

| Mesh Size | 200-325 |

| Iodine Number, mg/g | 1200 |

| Specific Surface Area, ㎡/g | 1200 (min) |

Methylene Blue, mg/g | 170 |

| Moisture, % | 10 (max) |

| Ash, % | 15 (max) |

Note: Specifications and particle sizes can be customized according to customer requirements.

Features

Exceptional Adsorption Efficiency: The advanced porous structure of this activated carbon effectively captures a range of pollutants including sulfur dioxide (SO2), nitrogen oxides (NOx), and mercury (Hg) present in flue gases.

Low Ash Levels: The reduced ash content minimizes the potential for secondary emissions, enhancing the overall efficiency of the gas treatment process.

Superior Thermal Stability: The coal-derived formulation provides remarkable thermal resilience, making this activated carbon suitable for the high-temperature conditions often encountered in industrial flue gas applications.

Economically Viable Production: Streamlined manufacturing processes combined with the availability of raw materials make this powdered activated carbon a cost-effective choice for large-scale operations.

Applications

Energy Sector: Often utilized to lower emissions from coal-powered plants, helping to meet environmental compliance regulations.

Cement Manufacturing: Efficiently absorbs harmful gases emitted during the cement production process, supporting more environmentally friendly manufacturing practices.

Waste Management: Plays a vital role in reducing harmful emissions and particulates during waste incineration, thereby improving air quality.

Metal Manufacturing: Used to treat emissions arising from steel production, boosting operational efficiency and regulatory compliance.

Chemical Industry: Aids in managing emissions from chemical production facilities, ensuring adherence to strict environmental standards.

Manufacturing Process

High-Quality Material Selection: Premium coal is carefully selected based on its attributes to ensure maximum performance in both activation and adsorption.

Carbonization Process: The coal is subjected to a high-temperature treatment in an oxygen-deprived environment, transforming it into activated carbon while maintaining its crucial porous characteristics.

Activation Techniques: The resulting carbon undergoes either chemical or physical activation methods that enhance its pore structure and surface area for improved adsorption.

Grinding Process: Post-activation, the carbon is finely milled to achieve the preferred particle size, optimizing its effectiveness for flue gas treatment.

Quality Testing: Each production batch is rigorously evaluated for key attributes, including iodine number, particle size, surface area, and moisture content to ensure adherence to quality standards.

Packaging for Distribution: The finished powdered activated carbon is packaged with care to fulfill diverse customer requirements for distribution.

Packaging Options

Standard Packaging: Usually available in 25 kg bags, providing convenience in handling and safeguarding during transport and storage.

Bulk Packaging: For larger orders, options like 500 kg bulk bags or container solutions are offered for streamlined logistics.

Custom Packaging: We can customize packaging options according to specific customer preferences, including various bag sizes, labeling, and bulk delivery configurations.

Moisture-Proof Packaging: All packaging designs include moisture-resistant features to protect the powdered activated carbon from environmental impacts that could affect its quality during storage.

|